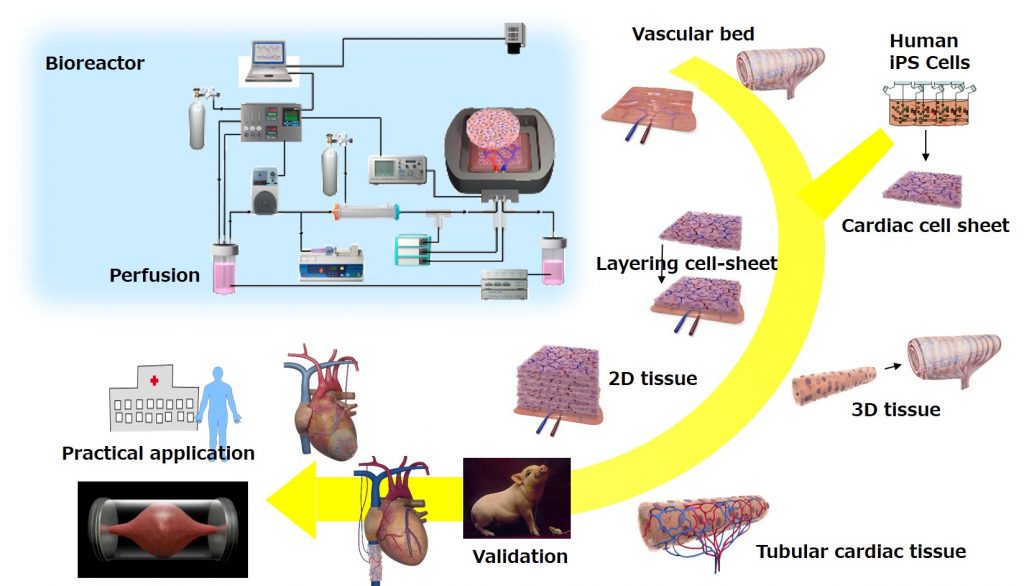

Fabrication of 3D tissues/organs with vascular network developed

We are pursuing to make methodology to fabricate artificial 3D tissue and organ with cell-sheet based engineering. So far, in order to more efficient supply O2 to and removal of waste materials from the 3D tissues, we have successfully fabricated 3D cardiac tissue with step-by-step cell-sheets-transplantation method as we developed. We are also developing new bioreactor systems, which were consisting of vascular bed and micro-perfusion flow channel and have been challenging to regenerate 3D cardiac tissues with developed vascular network by using the new bioreactor system. Moreover, we are trying to promote fabrication of tubular cardiac tissues, which enable to assist pulsation of hear organ. Based on these technologies, we are further challenging to fabricate thicker tubular cardiac tissue with stronger pulsation as well as developing advanced bioreactor system, which mimics in vivo environment. It is anticipated hear failure would be recovered by transplanting such tubular cardiac tissue.

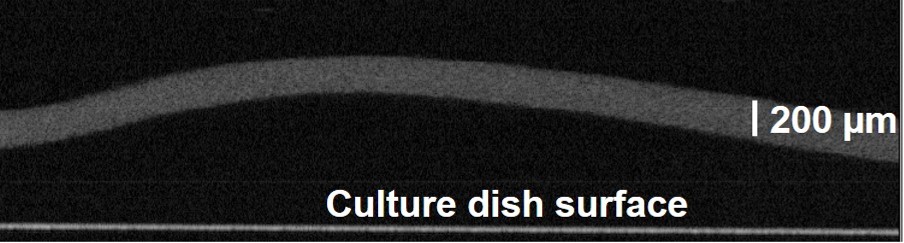

Rapid fabrication of transplantable three-dimensional tissues with centrifugation

The transplantation of a multi-layered three-dimensional (3-D) tissue demonstrates better therapeutic efficacies and stronger tissue-regeneration as compared to the injection of single cells. Three-dimensional tissues can be fabricated by cell-cell adhesion via adhesion proteins. We postulate that the heating centrifugation at 37C accelerates the fabrication of a 3-D tissue biologically (the acceleration of cell-cell adhesion) as well as physically (centrifugal force). Thus, our laboratory has developed a heat controlled centrifuge for rapid fabrication of transplantable 3-D tissues. The heating centrifugation system shortened the fabrication time of a transplantable 3-D tissue significantly compared to a system without centrifugation.

Tissue Factory – The first fully automated manufacturing system for regenerative medicine –

In order to produce high quality cell sheets, large aseptic facilities and trained technicians are required. This is a drag on delivering cell sheet products to more patients. Therefore, we are developing a flexible modular platform (fMP), a completely new manufacturing facility for regenerative medicine which is fully automated by utilizing industrial robots and isolator technology. A module that is a building block of fMP has only one simple function such as “seeding cells”, but various complex processes can be realized by combining several modules. Based on this design platform, the FIRST program led by Professor Teruo Okano worked with Professor Masahiro Kino-oka of Osaka University and many other companies to create the world’s first fully automated manufacturing system for multilayered skeletal muscle myoblast sheets, and named it “Tissue Factory”. In addition, we are currently working on the development of a regenerative medicine manufacturing facility utilizing human iPS cells based on the fMP.

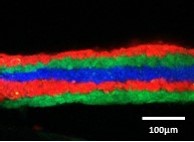

Automatic cell culture system

Layered skeletal myoblast sheets with the automatic cell-culture system